OPC UA Connection - Inverted pendulum example¶

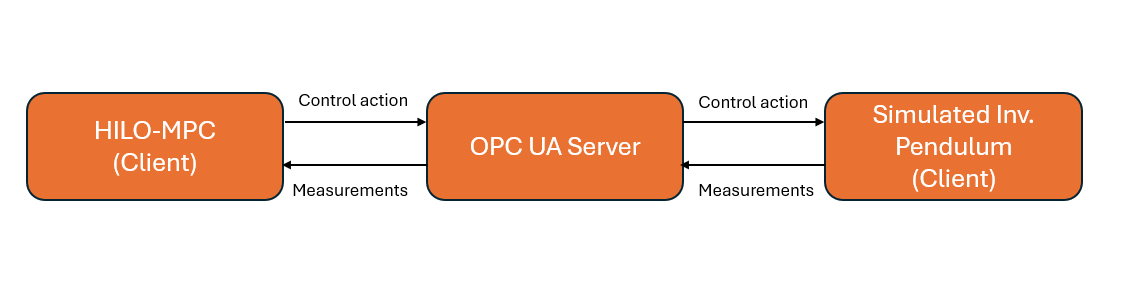

Do you want to connect HILO-MPC with actuators and sensors operating in the real world? HILO-MPC comes with an integrated interface to OPC UA that let you connect to external devices effortlessly.

In this example you will learn how to use the HILO-MPC OPC UA interface. We will test it with a (simulated) inverted pendulum problem, in a software-in-the-loop fashion. All the files used for this example can be found in our example repository in the folder opcua_pendulum.

Inverted pendulum connected via OPC UA: server exposes angle/torque; controller reads/writes.¶

Pendulum simulation¶

Let us begin by starting the UPC UA server, and then the server that simulates the inverted pendulum.

In the example repository navigate to the folder opcua_pendulum and run the following commands in two separate terminal windows:

# Start the OPC UA server

python3 opcua_pendulum_server.py

Then in another terminal window run:

python3 opcua_pendulum_dashboard.py

The terminal should output something like this:

Dashboard at http://127.0.0.1:8000/ (endpoint opc.tcp://127.0.0.1:4840/freeopcua/pendulum/, ns-idx 2)

If you click on the link, you should see a dashboard on your browser that shows the pendulum. This is reading the torque from the OPC UA server and updating the pendulum position accordingly. In the next section we will build a controller that sends the torque commands to the server.

Simple control loop¶

HILO-MPC comes with a built-in control loop that communicates with an OPC UA server. This can be already enough for simple control tasks. If you want to have more control, you can also build your own control loop using as shown in the next sections.

We want to control an inverted pendulum in the upright position using nonlinear MPC. First, let us define the MPC controller

def build_pendulum_nmpc(Ts_ctrl: float) -> NMPC:

"""NMPC around upright using phi = theta - pi to avoid wrap at ±pi."""

model = Model()

x = model.set_dynamical_states(["phi", "omega"]) # reparameterized angle

u = model.set_inputs(["u"]) # torque

phi = x[0]

omega = x[1]

torque = u[0]

ode = [

omega,

(g / l) * ca.sin(phi) - (c / I) * omega + (1.0 / I) * torque,

]

model.set_equations(ode=ode)

model.discretize("erk", order=4, inplace=True)

model.setup(dt=Ts_ctrl)

mpc = NMPC(model)

mpc.horizon = 20

mpc.quad_stage_cost.add_states(names=["phi", "omega"], ref=[0.0, 0.0], weights=[25.0, 2.0])

mpc.quad_terminal_cost.add_states(names=["phi", "omega"], ref=[0.0, 0.0], weights=[25.0, 10.0])

u_max = 5.0

mpc.set_box_constraints(u_lb=[-u_max], u_ub=[u_max])

mpc.set_initial_guess(x_guess=[0.0, 0.0], u_guess=[0.0])

mpc.setup(options={"objective_function": "discrete"})

return mpc

Since the OPC UA server provides the raw angle theta, but our NMPC controller works with the reparameterized state phi = theta - pi (to avoid discontinuities at ±π), we need an adapter that bridges this mismatch. The PendulumNMPCAdapter wraps our NMPC controller and performs three key tasks:

State transformation: Converts the raw angle theta from the server to phi = theta - pi

State augmentation: Estimates the angular velocity omega using finite differences between successive angle measurements

Interface compatibility: Provides a SimpleControlLoop-compatible optimize(x) method that the OPCUASimpleControlLoop can call

Here is the adapter implementation:

class PendulumNMPCAdapter:

"""Adapter presenting a SimpleControlLoop-like optimize(x) for OPCUASimpleControlLoop.

The incoming x is a 1-element vector [theta]. We internally construct

[phi, omega] and call the wrapped NMPC.optimize().

"""

type = "NMPC" # so OPCUASimpleControlLoop treats this as MPC for optimize()

def __init__(self, nmpc: NMPC, Ts_ctrl: float) -> None:

self.nmpc = nmpc

self.Ts = float(Ts_ctrl)

self._phi_prev: Optional[float] = None

@staticmethod

def _wrap_to_pi(a: float) -> float:

while a <= -math.pi:

a += 2 * math.pi

while a > math.pi:

a -= 2 * math.pi

return a

def is_setup(self) -> bool:

return True # underlying NMPC already set up

def optimize(self, x: Sequence[float], cp=None): # SimpleControlLoop-compatible

theta = float(x[0]) if len(x) > 0 else 0.0

phi = self._wrap_to_pi(theta - math.pi)

if self._phi_prev is None:

omega = 0.0

else:

dphi = self._wrap_to_pi(phi - self._phi_prev)

omega = dphi / self.Ts

self._phi_prev = phi

return self.nmpc.optimize([phi, omega], cp=cp)

Now we instantiate the adapter with our NMPC controller:

nmpc = build_pendulum_nmpc(Ts_ctrl)

ctrl = PendulumNMPCAdapter(nmpc, Ts_ctrl)

We then need to map the control actions and measurements from the HILO-MPC model to the OPC UA server nodes.

# Explicit mapping and loop

mapping = IOMapping(

reads={

"theta": {"node": f"ns={args.ns_idx};s=Pendulum/Angle_rad"},

},

writes={

"u": {"node": f"ns={args.ns_idx};s=Pendulum/Torque_Nm"},

},

)

Finally we can start the control loop by running

loop = OPCUASimpleControlLoop(

endpoint=args.endpoint,

mapping=mapping,

controller=ctrl,

estimator=None,

state_aliases=["theta"],

control_aliases=["u"],

parameter_aliases=[],

period=args.Ts_ctrl,

reconnect_backoff=tuple(args.reconnect),

safe_shutdown={"u": 0.0},

)

print("OPC UA pendulum (OPCUASimpleControlLoop) started. Ctrl+C to stop.")

loop.run_sync(max_iters=args.iters)

The full code that uses the OPCUASimpleControlLoop is the file opcua_simple_control_loop.py in the example folder. When you run this script

python3 opcua_simple_control_loop.py

you should see the pendulum moving to the upright position as the controller sends torque commands to the OPC UA server. When you terminate the script, the safe shutdown command will set the torque to zero. You should see the pendulum moving to resting position downwards.

Flexible control loop¶

While OPCUASimpleControlLoop is convenient for basic applications, you may need more control over

the execution flow for advanced scenarios such as:

Custom logging and data collection

Complex state estimation or filtering

Conditional logic between reading sensors and computing control actions

For these cases, HILO-MPC provides the OPCUAConnector class, which gives you direct access to

read and write operations while you manage the control loop yourself.

The full code of the flexible loop can be found in the example repository as opcua_pendulum_controller.py. This file

is basically an alternative to opcua_simple_control_loop.py, providing more flexibility for advanced use cases.

Setting up the OPC UA connector¶

First, create an OPCUAConnector instance with the same I/O mapping as before:

from hilo_mpc import OPCUAConnector, IOMapping

mapping = IOMapping(

reads={

"theta": {"node": f"ns={args.ns_idx};s=Pendulum/Angle_rad"},

},

writes={

"u": {"node": f"ns={args.ns_idx};s=Pendulum/Torque_Nm"},

},

)

connector = OPCUAConnector(

endpoint=args.endpoint,

mapping=mapping,

)

connector.connect()

The connector provides two key methods: read() to fetch measurements from the OPC UA server,

and write() to send control actions back.

Building a custom control loop¶

With the connector, you can now build your own control loop with full flexibility:

import time

# Build controller and adapter as before

nmpc = build_pendulum_nmpc(Ts_ctrl)

ctrl = PendulumNMPCAdapter(nmpc, Ts_ctrl)

try:

while True:

t_start = time.perf_counter()

# Read current state from OPC UA server

measurements = connector.read()

theta = measurements["theta"]

# Compute control action

solution = ctrl.optimize([theta])

u_opt = solution.u[0, 0]

# Write control action to OPC UA server

connector.write({"u": u_opt})

# Optional: Log or process data here

print(f"θ={theta:.3f} rad, u={u_opt:.3f} Nm")

# Wait for next control cycle

elapsed = time.perf_counter() - t_start

time.sleep(max(0, Ts_ctrl - elapsed))

except KeyboardInterrupt:

print("\nShutting down...")

connector.write({"u": 0.0}) # Safe shutdown

finally:

connector.disconnect()

This custom loop gives you complete control over timing, error handling, and data processing. You can:

Add customized filters or observers between reading and optimization

Implement multi-threaded control with separate read/compute/write tasks

Store data to files or databases during operation

Handle connection failures with custom retry logic

You can run the flexible control loop script with:

python3 opcua_pendulum_controller.py

(remember to start the server and dashboard first as shown previously). You should see the pendulum moving to the upright position as before.

Comparison: Simple vs. Flexible approach¶

Choose OPCUASimpleControlLoop when:

You have a straightforward sense-compute-actuate cycle

Standard timing and error handling is sufficient

You want minimal boilerplate code

Choose OPCUAConnector with a custom loop when:

You need fine-grained control over execution order

You want to add custom processing between control steps

You need to integrate with other systems or data pipelines

You require custom error handling or logging strategies

Both approaches use the same underlying OPC UA communication layer, so you can start with the simple approach and switch to the flexible one as your requirements grow.

Security and Authentication¶

In production environments, OPC UA servers typically require authentication and encrypted communication.

HILO-MPC supports both username/password authentication and certificate-based security through optional

parameters available in both OPCUASimpleControlLoop and OPCUAConnector.

Username and Password Authentication¶

The simplest form of authentication uses username and password credentials:

loop = OPCUASimpleControlLoop(

endpoint="opc.tcp://192.168.1.100:4840/secure/server/",

mapping=mapping,

controller=ctrl,

username="operator",

password="secure_password",

period=0.02,

)

The same parameters work with OPCUAConnector:

connector = OPCUAConnector(

endpoint="opc.tcp://192.168.1.100:4840/secure/server/",

mapping=mapping,

username="operator",

password="secure_password",

)

Certificate-based Security¶

For higher security requirements, OPC UA supports certificate-based encryption and signing. You need to provide the security mode, security policy, and paths to your certificate and private key files:

loop = OPCUASimpleControlLoop(

endpoint="opc.tcp://192.168.1.100:4840/secure/server/",

mapping=mapping,

controller=ctrl,

security_mode="SignAndEncrypt",

security_policy="Basic256Sha256",

cert_path="/path/to/client_cert.der",

key_path="/path/to/client_key.pem",

username="operator",

password="secure_password",

period=0.02,

)

Available Security Modes¶

The security_mode parameter accepts the following values from the OPC UA specification:

"None": No security (default, used in examples)"Sign": Messages are signed but not encrypted"SignAndEncrypt": Messages are both signed and encrypted (recommended for production)

Available Security Policies¶

The security_policy parameter determines the cryptographic algorithms used:

"None": No security policy"Basic128Rsa15": RSA 1.5 encryption with 128-bit AES (deprecated, use only for legacy systems)"Basic256": RSA OAEP encryption with 256-bit AES"Basic256Sha256": RSA OAEP with SHA-256 (recommended)"Aes128_Sha256_RsaOaep": Modern algorithm suite with AES-128"Aes256_Sha256_RsaPss": Strongest algorithm suite with AES-256 (recommended for high security)

Note

The security policies available depend on the server configuration. Consult your OPC UA server documentation to determine which policies are supported.